Home» Construction Material Analysis» Non-destructive Testing

Non-destructive Testing

Non-destructive testing (NDT) plays a vital role in assessing and ensuring the stability and structural integrity of buildings without causing any harm or damage. In the context of building stability, NDT methods are employed to detect potential flaws, weaknesses, or deterioration in structural elements.

The Rebound Hammer (IS 516 Part 5/ Section 4)

Test is a non-destructive method used to assess the compressive strength of concrete. It involves striking the concrete surface with a spring-loaded hammer and measuring the rebound distance. The rebound value is compared to established charts to estimate concrete strength. It’s a quick way to check the quality of concrete in construction, but it provides only an approximate strength value and should be followed up with more precise testing if necessary.

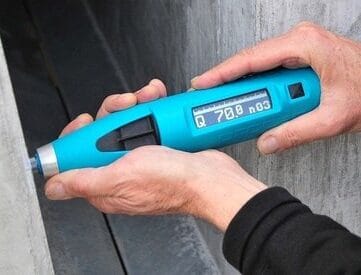

Ultrasonic Pulse Velocity (IS 516 Part 5/ Section 1)

Non-destructive testing method used to assess the integrity and quality of concrete and other construction materials. It works by sending high-frequency sound waves through the material and measuring the time it takes for the waves to travel through it. The velocity of the sound waves is directly related to the material’s density and the presence of any defects or anomalies.

Core cutting & Compressive strength (IS 516 Part 1/ Section 1)

Core cutting is a process that involves drilling and extracting cylindrical samples (cores) from concrete structures to assess their quality, integrity, and properties, such as compressive strength.

Compressive strength is a measure of a material’s ability to withstand axial loads or forces applied in a pushing or compression direction.