Home» Pharmaceutical Analysis» Analytical Method Development & Validation

Analytical Method Development & Validation

Analytical methods used for assessing compliance of pharmaceutical articles with established specifications are required to meet proper standards of accuracy and reliability [21 CFR 211.194(a)].

CLL uses guidance provided by respective chapters of USP <1225> & Ph.Eur. along-with ICH Q2 (“Validation of Analytical Procedures: Text and Methodology”) guidelines to carry out Analytical Method Validation. For submissions to Latin American markets (LATAM), Resolution RDC No. 166 (ANVISA) is followed.

CLL’s Approach to Analytical Method Development:

Analytical Method Development captures 90% of the work required for any successful validation.

Step 1: Sample characteristics

The first step in Analytical Method Development is establishing the sample characteristics such as solubility, Pka values, pH, boiling point / volatility, chemical formula / functional groups present, reactivity etc. Based on this the correct technique can be selected.

Step 2: Literature review

Review of available information on the molecule of interest can provide information on regulatory guidance, scientific literature, potential methods or interferences.

Step 3: Development plan

Next, a development plan is formulated with multiple experiments. With each experiment the method undergoes further optimization. At this stage a method outline in principle is developed.

Step 4: Optimize method with respect to Study Goals

Study goals outlined before the Analytical Method Development process are reviewed to align the method into a more targeted study. Following study goals are to be considered:

- Market / Regulatory agency: Specific guidelines are to be reviewed for each market with their requirements.

- Identification and interference check: from all related impurities or analytes is required.

For e.g. 52Cr isotope must be assessed against known interferences from 36Ar16O, 40Ar12C, 35Cl16OH, 37Cl14NH during ICP-MS method development.

- Adequate detection limit: Method must be optimzied to meet sufficient sensitivity. For e.g. clients or regulators may define LOQ to be established at a certain value.

- Linear range: Based on the specification limit and the regulatory guidance, the linear range of the method is required to be established.

For e.g. With a Permitted Daily Exposure (PDE) limit of 10ppm, and a Maximum Daily dose of 10grams, the method target specification limit is established as 1ppm. With an LOQ requirement of 10% , linear range must be established from 0.1ppm to 1.5ppm (150% of the specification limit).

- Multiple vendors or grades: Method may be required to cover various dosage strengths, grades or vendors, and therefore, specificity maybe required for each grade.

- Flexibility: If the method is going to be used on multiple locations with various models of instruments, the method development has to be planned to ensure that technology transfer can be carried out at a later stage on all available instruments models in the plant.

Step 5: Propose Acceptance Criteria

Once the method is optimized and aligned to the study-goals, the developed method can be checked against proposed acceptance criteria. The acceptance criteria for any specific technique maybe available from general chapters such as USP<852> / Ph.Eur. 2.2.23 etc. or from internal SOPs.

Pre-Validation checks on developed method

Before the final developed method is taken up for validation, it has to be checked to ensure that it will meet the validation requirements. At CLL, we carry out at the following minimum pre-validation checks:

- Specificity

- Linearity with LOD/LOQ estimation

- Accuracy for the range determined

- System precision

- System Suitability

- Solution stability

- Filter selection study

- Sample characteristics

- Literature review

- Development Plan

- Optimization w.r.t. Study goals

- Proposed Acceptance criteria

Developed method

Pre-Validation Checks

Analytical Method Validation Elements

CLL uses USP classification system to determine the elements for the validation study. The matrix below is used as a broad framework for initial design, and then based on client feedback, the study protocol is finalized.

Category I

Analytical procedures for quantitation of major components of bulk drug substances or active ingredients (including preservatives) in finished pharmaceutical products

Category II

Analytical procedures for determination of impurities in bulk drug substances or degradation compounds in finished pharmaceutical products. These procedures include quantitative assays and limit tests.

Category III

Analytical procedures for determination of performance characteristics (e.g., dissolution, drug release, and others).

Category IV

Identification Tests

Regulatory References

- Analytical Procedures and Methods Validation for Drugs and Biologics, Guidance for Industry, US-FDA.

- USP 〈1225〉 : Validation of Compendial Procedures , 〈1226〉 : Verification of Compendial Procedures.

- International Conference on Harmonisation (ICH) Harmonised Tripartite Guideline: Validation of Analytical Procedures: Text and Methodology Q2(R1)

- FUKUMA RESOLUTION OF THE COLLEGIATE BOARD – RDC Nº. 166, DATED JULY 24th, 2017

Analytical Method Validation

For regulatory submissions, the type of method selected and its suitability demonstration are extremely important. At CLL, each validation study is designed keeping in mind the end study goals and the regulatory authority requirements. Typically, a quantitative method validation covers, following parameters:

Selectivity & Specificity

- Identification

- Blank Interference

- Response in presence of Related or native analytes

System Suitability

- Initial Calibration verification

- Resolution, Theoretical plates, Symmetry.

- Regression

- Sensitivity Check (s/n)

- Ion ratio

- Continuing Calibration verification

Solution stability

- Standard & Sample solutions

- Bench-top

- Sampler

- Refrigerated

- Hold-time studies

Linearity

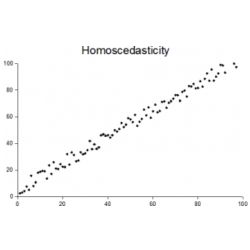

- Coefficient of correlation & determination

- Angular coefficient

- Residuals Dispersion & RSS

- Homoscedasticity

Precision & Bias

- System Precision

- Method Precision

- Bias

- Measurement Uncertainty

- Confidence Interval

- Continuing Calibration verification

Ruggedness

- Intra-lab: Variance from alternate analyst / day / instrument / column

- Inter-lab: Collaborative studies

- Cumulative Confidence Interval

- Hypothesis testing

Range & Accuracy

- Recovery at Min. & Max. range

- Matrix effect

Filter Compatibility

- Impact on Standard solution

- Impact on Sample / Spiked sample solution

Robustness

- Extraction efficiency

- Impact of Variation due to:

- pH/Mobile phase composition

- Column & Sampler temperature

- Flow rate or program

Other critical parameters

Limit of Detection

- Estimation

- Confirmation

- S/N ration

Limit of Quantitation

- Estimation

- Confirmation

- S/N Ration

- Accuracy & Precision at LOQ

Tech-Transfer

- Direct

- Indirect

- Collaborative